ICHI BAN MOULD TECH INDUSTRIES

SDN BHD

About

Leading Moulding Technical Know-How in Northern Region of Malaysia since 1990

.

THE PROCESS

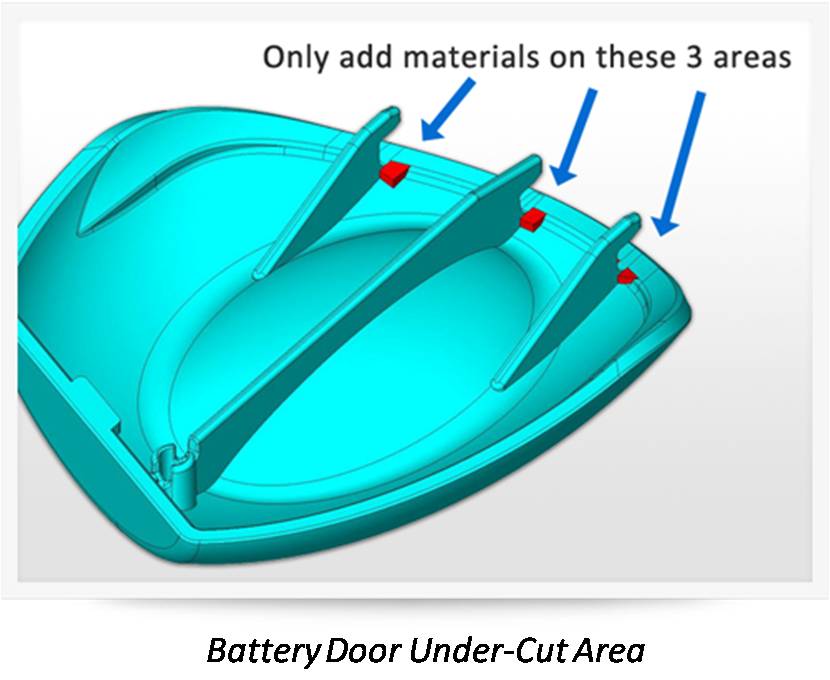

1. Tooling Conceptual Stage

Customer submission of product design

Design team will begin the assessment and Design For Manufacturing

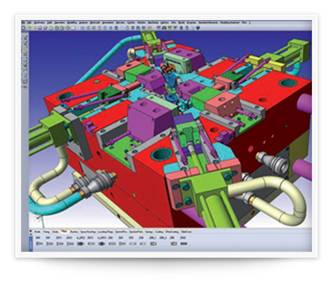

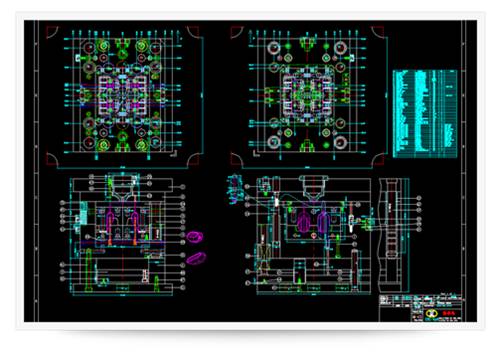

2. Tooling Design

We are equipped with various kind of engineering software , cater to your requirements standard

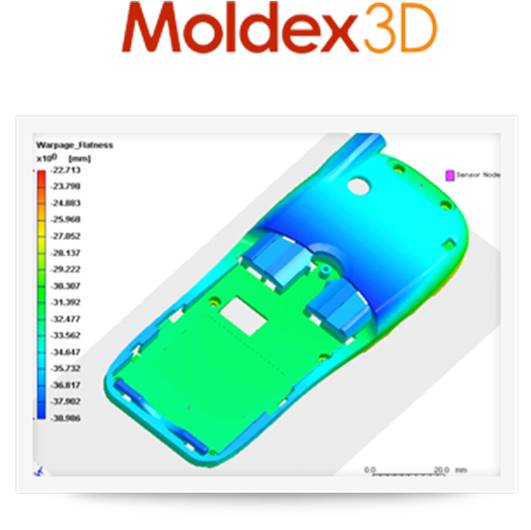

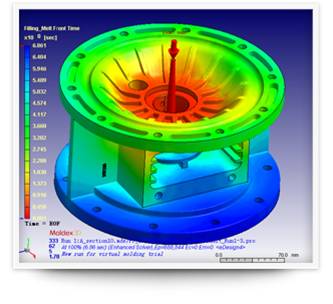

3. Product Analysis

4. Flow Analysis Software

5. Technical Drawing Fabrication

6. Milling Process

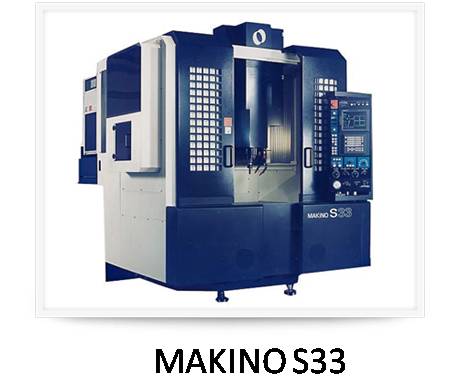

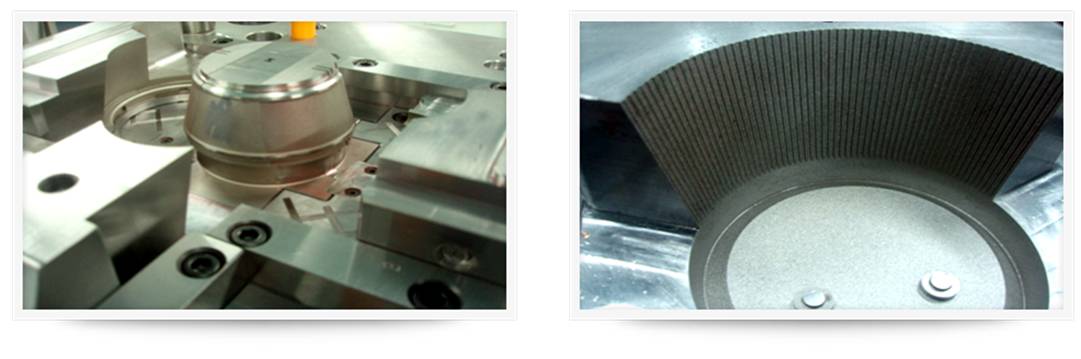

7. CNC Milling Process

Our Enthusiasm Of High Speed Machines

Because we aim for Quality, Faster time, and Cost Effective

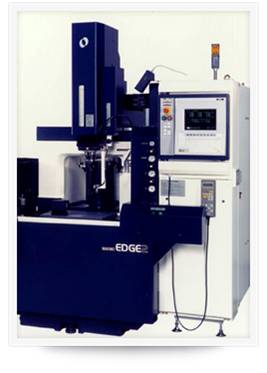

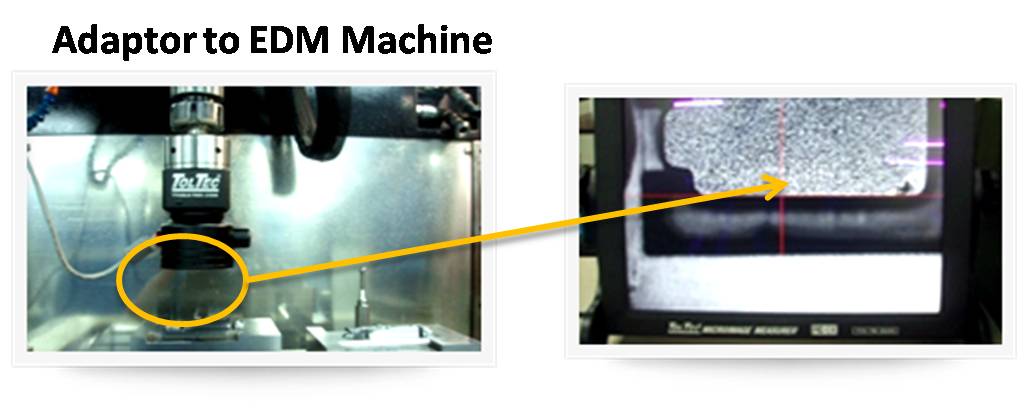

8. CNC EDM Process

MAKINO EDM CNC – EDGE 2S

10. Wire-Cut & Super Drill Process

11. Polishing Process

In-house Polishing Department with Experienced and Dedicated staffs

12. QA Process

13. Hot Runner Systems

Our hot runner system suppliers are:

- Mastip (New Zealand)

- YUDO (Korea)

- Sinhot (Singapore)

- Hotsys (Korea)

Many other from USA and Europe

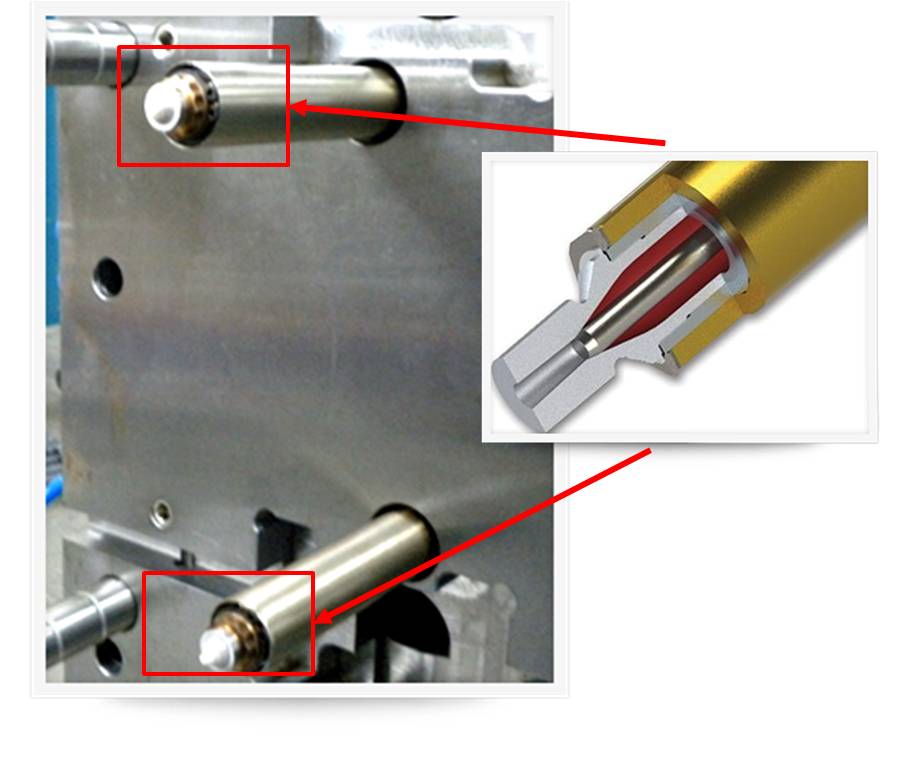

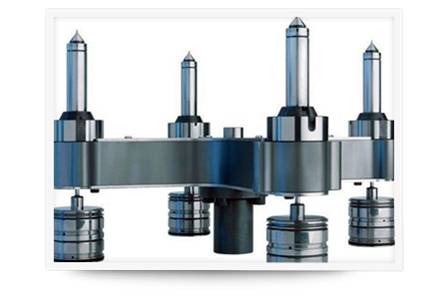

Valve Gate System

Hot Tip with Manifold System

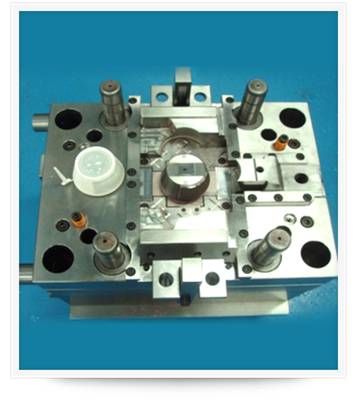

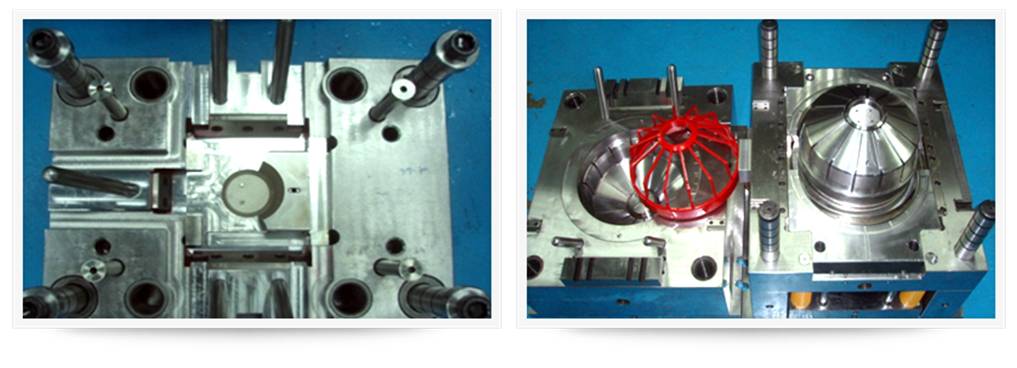

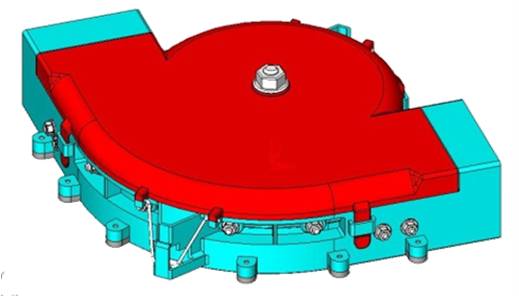

14. Tooling Details

Agriculture Tooling

Size (WxLxH): 800x1350x530mm

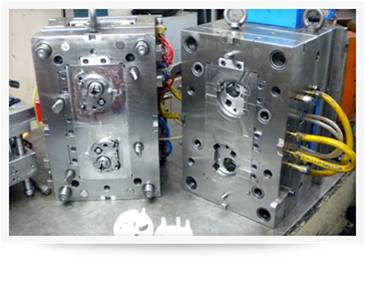

Automotive Tooling with Valve Gate System

Size (WxLxH): 350x550x675mm

More Tooling Details

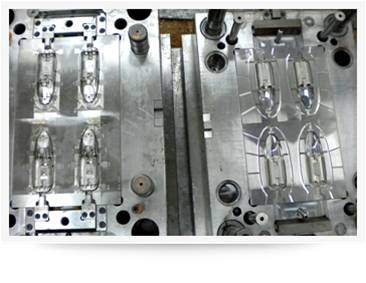

Cosmetic Part Tooling (High Polishing)

Tooling Size (WxLxH): 350x500x370mm

Automotive Tooling

Tooling Size (WxLxH): 350x350x330mm

15. Complete Assemble Tools

Collapsible Tools

Die Casting Mould